Expert maintenance services biomedical equipment repair ensure your healthcare facility maintains optimal device performance for critical patient care and regulatory compliance.

When patient safety and clinical outcomes depend on reliable medical technology, equipment servicing becomes essential for maintaining optimal healthcare delivery and ensuring life-support systems function flawlessly. Professional maintenance solutions ensure your critical medical devices perform reliably when patients need them most, preventing equipment failures that could compromise care quality and endanger lives.

The Critical Importance of Maintenance in Healthcare Safety

When Medical Device Failures Require Emergency Service

Equipment maintenance represents the most critical service in healthcare environments where reliability directly determines patient outcomes and survival rates. Medical device malfunctions requiring immediate attention can result in life-threatening situations, compromised patient monitoring, medication delivery errors, and respiratory support failures. A malfunctioning ventilator, failed defibrillator, or inaccurate infusion pump needing urgent service can transform routine patient care into emergency situations where seconds matter and equipment reliability determines survival.

The life-threatening consequences of delayed servicing biomedical equipment repair cannot be overstated in healthcare settings. Consider the critical scenarios when medical devices require emergency attention:

- Ventilator Failures: Respiratory support equipment needing service can cause immediate patient danger

- Monitor Malfunctions: Vital signs monitoring systems requiring attention create dangerous blind spots

- Infusion Pump Errors: Medication delivery devices needing calibration can cause overdoses or underdoses

- Defibrillator Problems: Cardiac emergency equipment requiring service can prevent life-saving interventions

- Dialysis Equipment Issues: Renal support systems needing maintenance can threaten patient stability

Statistical Reality of Equipment-Related Incidents: Studies from the FDA reveal that medical device malfunctions contribute to over 5,000 serious injuries annually, with equipment failures representing a significant portion of these incidents. Hospital risk management data shows that facilities with comprehensive maintenance programs experience 60% fewer equipment-related adverse events compared to those relying on reactive approaches.

Emergency Response During Device Failures: When urgent servicing becomes necessary during patient care, healthcare teams face impossible situations where backup equipment may not be immediately available biomedical equipment repair or adequate for complex patient needs. Emergency substitutions rarely match the specific requirements of failed devices, making preventive maintenance essential for maintaining continuous, optimal patient care capabilities.

The Financial Impact of Delayed Maintenance on Healthcare Facilities

Beyond immediate patient safety concerns, equipment failures create devastating financial impacts throughout healthcare organizations. The economics of servicing extend far beyond simple repair costs, encompassing emergency rentals, procedure cancellations, liability exposure, and regulatory penalties that can severely impact institutional budgets and operational sustainability.

Emergency Equipment Rental Costs: When critical equipment fails and requires attention, healthcare facilities often resort to emergency rentals at premium rates that can cost thousands of dollars daily. Ventilator rentals during service periods can cost $800-$1,500 per day, while specialized equipment like ECMO machines may exceed $4,000 daily. Extended repair timelines can consume tens of thousands in rental costs while compromising patient care quality.

Revenue Loss from Procedure Cancellations: Equipment failures often force healthcare facilities to cancel high-revenue procedures and diagnostic tests. A failed CT scanner can eliminate $15,000-$30,000 in daily imaging revenue, while surgical equipment failures can cancel multiple procedures worth hundreds of thousands in lost revenue plus associated rescheduling costs.

Liability and Insurance Implications: Healthcare facilities face substantial liability exposure when equipment failures contribute to patient injuries or adverse outcomes. Even minor malfunctions can result in multi-million dollar settlements when they contribute to patient harm, making proactive servicing a critical component of risk management strategies.

Regulatory Compliance Costs: The Joint Commission and FDA require healthcare facilities to maintain comprehensive equipment management programs, including regular maintenance. Repeated equipment failures can trigger regulatory investigations, accreditation reviews, and potential penalties that far exceed the cost of preventive services.

Studies demonstrate that healthcare facilities with comprehensive maintenance programs reduce total equipment-related costs by 40-60% compared to reactive approaches, while simultaneously improving patient safety outcomes and regulatory compliance.

Expert Solutions for All Medical Devices biomedical equipment repair

Comprehensive Diagnostic and Restoration Through Professional Services

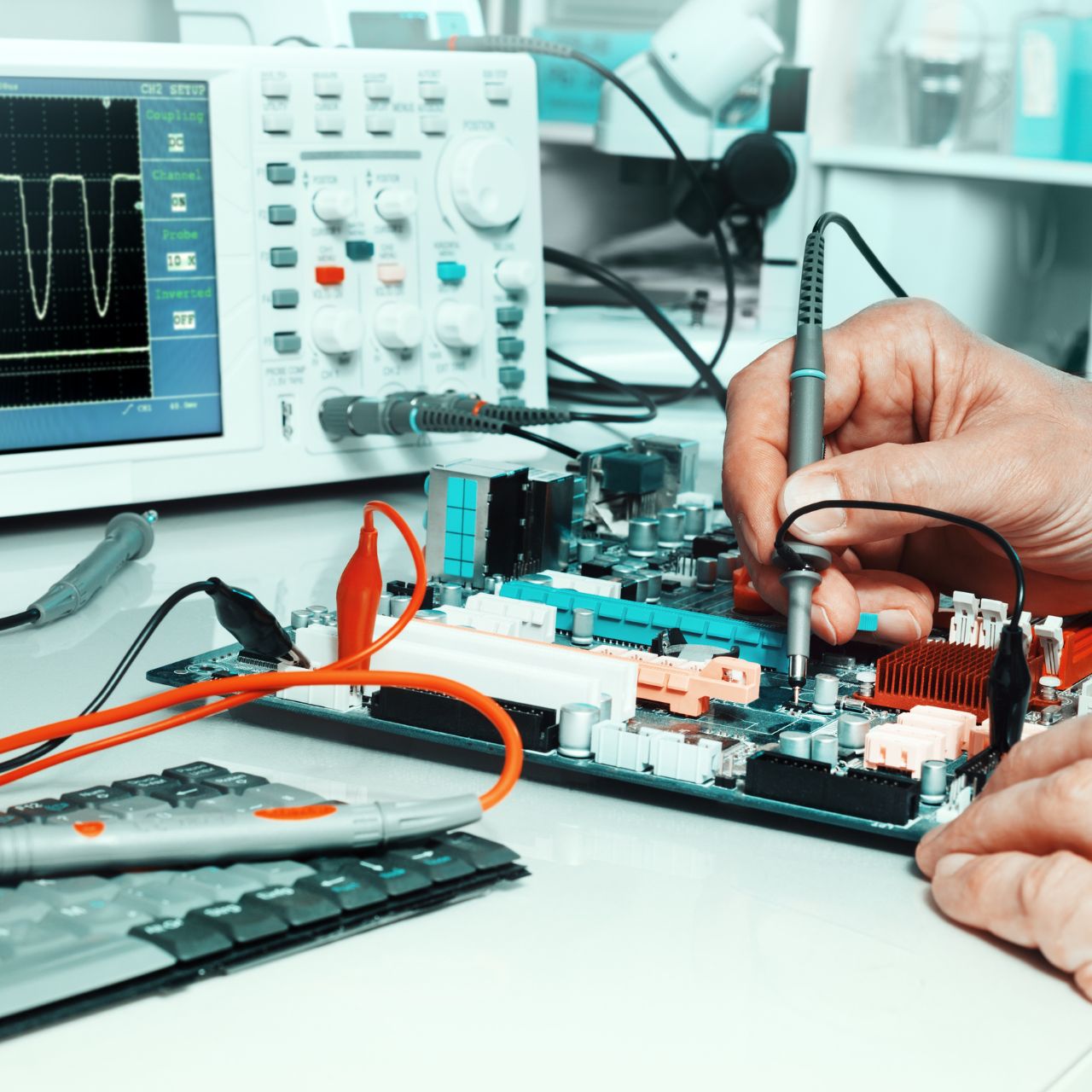

Our certified biomedical technicians provide comprehensive maintenance for all categories of medical devices, utilizing advanced diagnostic equipment and maintaining extensive inventories of OEM parts to ensure rapid, reliable service that meets or exceeds manufacturer specifications. We understand that medical equipment servicing requires specialized knowledge of complex technologies, regulatory requirements, and patient safety standards.

Patient Monitoring System Service: Maintenance for monitoring systems includes comprehensive restoration of vital signs monitors, cardiac telemetry systems, hemodynamic monitors, and pulse oximetry equipment from manufacturers including Philips, GE Healthcare, Mindray, and Nihon Kohden. Our services include sensor calibration, signal processing optimization, alarm system validation, and network connectivity restoration through expert techniques that ensure accurate patient monitoring.

Life Support Equipment Maintenance: Critical life support devices require specialized expertise to maintain optimal performance for patient survival. Our services include ventilator restoration, defibrillator testing and calibration, infusion pump accuracy verification, and dialysis machine maintenance. Professional attention ensures that life-critical equipment operates flawlessly when patients depend on it for survival.

Diagnostic Equipment Calibration: Laboratory and imaging equipment requires precise servicing to maintain diagnostic accuracy essential for proper patient care. Our services include analyzer calibration, centrifuge balancing, X-ray equipment maintenance, and ultrasound system restoration. Expert maintenance ensures that diagnostic equipment provides accurate, reliable results for clinical decision-making.

Surgical Equipment Service: Operating room equipment demands specialized attention to maintain surgical precision and patient safety during procedures. Our services include electrosurgical unit calibration, surgical table maintenance, anesthesia machine testing, and surgical light restoration. Professional servicing ensures that surgical equipment supports optimal outcomes and patient safety.

Advanced Calibration and Safety Testing

Medical equipment maintenance requires precise calibration and comprehensive safety testing to ensure devices meet manufacturer specifications and regulatory requirements. Our services include electrical safety testing, performance verification, accuracy validation, and alarm system testing that demonstrates equipment reliability.

Electrical Safety Testing: Every service project includes comprehensive testing according to IEC 60601 standards to ensure patient and operator protection. Our testing includes leakage current measurement, grounding verification, isolation testing, and dielectric strength validation. Professional servicing ensures that all electrical safety parameters meet or exceed regulatory requirements.

Performance Verification: Maintenance must include detailed performance testing to ensure devices operate within acceptable tolerances for clinical use. Our testing includes measurement accuracy verification, response time testing, stability assessment, and repeatability validation. Expert attention ensures that medical devices provide consistent, reliable performance for optimal patient care.

Alarm System Validation: Medical device alarms represent critical safety features that must function properly, making alarm testing essential during servicing. Our testing includes threshold verification, audibility testing, visual indicator validation, and response time measurement. Professional maintenance ensures that all alarm systems function properly to protect patient safety.

Preventive Programs That Minimize biomedical equipment repair Needs

Risk-Based Strategies for Critical Medical Equipment

Our preventive programs are designed to minimize emergency needs through strategic risk assessment and scheduled maintenance that prioritizes life-critical equipment and high-utilization devices. Risk-based approaches include performance monitoring, component replacement, calibration verification, and safety testing that prevents failures while optimizing resources and minimizing patient care disruptions.

Critical Equipment Prioritization: Maintenance programs must prioritize life-support and critical monitoring equipment that directly impacts patient survival. Our risk-based approach focuses intensive attention on ventilators, defibrillators, infusion pumps, and monitoring systems while optimizing schedules for less critical equipment. This strategic prioritization ensures critical equipment receives appropriate attention while managing resources effectively.

Predictive Technologies: Advanced diagnostic tools help identify developing problems before they require emergency attention. Our predictive approaches include performance trending, component testing, thermal analysis, and vibration monitoring that can predict equipment failures weeks or months in advance. Early detection allows for planned servicing during scheduled downtime rather than emergency situations.

Performance Optimization: Beyond preventing failures, our programs optimize equipment performance through strategic maintenance that ensures devices operate at peak efficiency. Regular calibration, component replacement, and performance tuning help medical equipment deliver consistent results while extending operational lifespan through professional services.

Regulatory Compliance and Documentation

Medical equipment maintenance must meet stringent regulatory requirements including FDA regulations, Joint Commission standards, and healthcare facility accreditation requirements. Our services include comprehensive documentation, compliance verification, and performance certification that supports regulatory compliance.

Documentation and Record Keeping: Every service project includes detailed documentation that supports regulatory compliance and quality assurance requirements. Our records include service reports, calibration certificates, safety test results, and performance verification data that help healthcare facilities maintain compliance with regulatory standards.

Staff Training and Competency Verification: Proper equipment operation following servicing requires ongoing staff training and competency verification. Our programs include equipment operation, troubleshooting techniques, safety protocols, and maintenance procedures that help healthcare staff maximize performance while minimizing future service needs.

Quality Management: Maintenance programs should include quality systems that drive continuous improvement in reliability and performance. Our quality approach includes performance metrics, failure analysis, root cause investigation, and process improvement recommendations that help healthcare facilities optimize their programs for maximum effectiveness and patient safety.

Frequently Asked Questions biomedical equipment repair

Q: How quickly can you respond to emergency calls?

A: We offer 24/7 emergency services with response times typically within 1-2 hours for life-critical failures. Our technicians carry mobile repair kits and maintain local parts inventory for immediate attention when possible. For life-support equipment, we prioritize these calls above all others.

Q: Are your technicians certified for all equipment types?

A: Yes, our technicians hold advanced certifications including CBET credentials and maintain manufacturer-specific training for equipment from all major manufacturers. Our team includes specialists in life support systems, imaging equipment, laboratory devices, and surgical equipment.

Q: How do you ensure compliance with regulations?

A: All work follows FDA guidelines, IEC 60601 standards, and Joint Commission requirements. We provide detailed documentation including electrical safety testing, performance verification, and calibration certificates. Our processes are designed to meet or exceed all regulatory requirements.

Q: Do you provide preventive programs?

A: Yes, we offer comprehensive preventive programs specifically designed to minimize emergency needs through risk-based scheduling and predictive techniques. Our programs can reduce emergency requirements by 60-80% while extending equipment lifespan.

Q: What warranty do you provide?

A: We provide comprehensive warranties on all work, typically 90 days for parts and labor on most medical equipment. Our warranty includes performance guarantees and covers any issues related to our service. Extended options are available for critical equipment.

Ready to ensure your medical equipment operates safely and reliably? Contact Biomedical Fix Solutions today for expert biomedical equipment repair services that healthcare professionals trust for critical patient care.

WhatsApp: Get immediate repair assistance

Facebook: Follow us on Facebook

Instagram: Connect with us on Instagram

Website: Visit biomedicalfix.com

Our certified biomedical technicians specialize in biomedical equipment repair and are available 24/7 for emergency medical device repairs. When patient lives depend on reliable medical equipment, depend on us for expert biomedical equipment repair services that ensure optimal performance and safety.